EPOXY COVING

This inventive approach not only enriches the visual attractiveness of an area but also

serves a crucial function in preserving its structural stability and cleanliness.

What exactly is Floor Coving and what is it used for?

Carmacoat EPX Coving is a type of molding used to cover the edge of the floor where it meets the wall. They are generally rounded to provide a seamless transition from wall to floor. The width of the coving can vary depending on the requirement. By employing a conventional 45-degree rounded angle that inclines upwards, floor coving eradicates the sharp corner commonly observed at this intersection. This inventive approach not only enriches the visual attractiveness of an area but also serves a crucial function in preserving its structural stability and cleanliness.

Reasons why you need coving

Enhanced Hygiene

Easier to clean, reducing the risk of bacterial and fungal growth.

Wall Protection

Shields walls from damage caused by cleaning, furniture, and foot traffic.

Improved Aesthetics

Provides a smooth transition between wall and floor, enhancing the room’s appearance.

Durable

Protects against wear and tear, extending the life of the walls and flooring.

For these reasons, coving installations are usually required in companies and facilities where health and hygiene are heavily regulated (medical and pharmaceutical facilities, manufacturing plants, laboratories, etc.).

It is important to know that the coving installation should be done prior to the epoxy floor coating application. This section discusses the coving methodology and application. For epoxy floor coating application, see the methodology for epoxy floor systems in the previous section

How does cove work

- Surface Preparation- In the manner that surface preparation is essential in epoxy floor coating application, it is also a requisite for durable coving installations. For a smooth process throughout, ensure that the walls and flooring are clean, dry, and free from dust or debris. Any existing paint or wallpaper should be removed or smoothed out before installing the coving. First, grind down the floor surface with a mechanical hand grinder until the concrete is exposed. Define the desired measurements of the coving then apply tape on the wall and floor surfaces to map out the installation consistently. The offset width from the wall edge to the tape for both the flooring and the wall surface must be uniform to achieve a perfectly rounded cove. Sand the surface using a 60-grit sandpaper. Using a vacuum cleaner, clear the area of any dust and debris.

- Sealing the concrete

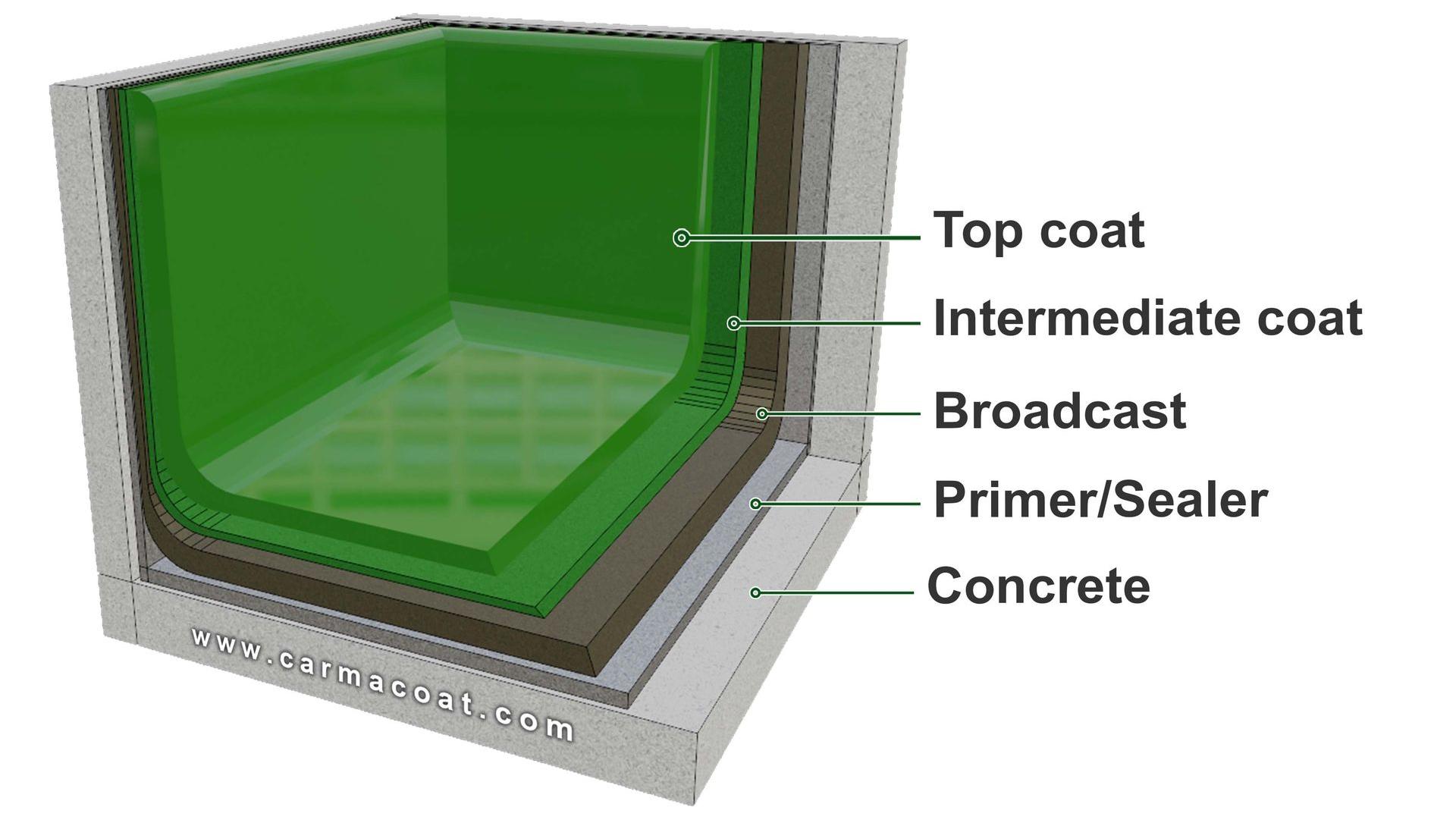

Make sure that the area is dry prior to the application of the epoxy paint. Mix the entire container of components thoroughly—this consists of Carmacoat Epoxy Primer [Clear] and Part B - Hardener [Self-priming]. Incomplete or improper mixing of epoxy components, epoxy Part A and B, can result in uneven curing and compromised performance so mix the two components well before using and allow an induction time of 10 minutes for the components to blend thoroughly.

Using a paintbrush, apply the epoxy thinly on both wall and floor surfaces where the coving will be installed. This will consume a small amount of the mixture—the remaining will be used in preparing the coving mixture.

- Installing the coving

Transfer the aggregate (Part C) onto a mixing tray and pour in the mixture that remained after sealing the concrete in the previous step. Mix manually until the epoxy is fully merged with the aggregate.

Apply the coving mixture on the entire surface that was taped of during surface preparation. Using a curved trowel or any cylinder (such as a PVC pipe) with the appropriate radius compatible with the coving area, repeatedly compress the mixture against the flooring and wall surfaces. Continue pressing down and pushing the cylinder up along the wall simultaneously until the coving is packed and has an intact and desirable curve. Remove the tapes, and proceed to press down and push the cylinder up a few more times until the seams are no longer noticeable, or are nicely blended where it meets the flooring and walls.

Make sure that each batch of coving mixtures is applied within 30 minutes of mixing or else the unapplied mixture will begin to cure and harden.

- Curing

The coving will be ready for a layer of epoxy coating to be applied on top of it once 4-6 hours of curing time has passed. It is usually coated together with the entire flooring to create a floor-to-wall coving that’s integrated into the epoxy coating.

When does cove require?

Floor coving is typically required in specific environments and situations where cleanliness, hygiene, and ease of maintenance are critical. Some of the common instances, when floor coving is required, include:

Pharmaceutical Manufacturing: Similar to healthcare facilities, pharmaceutical manufacturing areas require a high level of cleanliness to prevent contamination. Floor coving helps achieve this by eliminating hard-to-clean corners.

Food Processing and Preparation Areas: In kitchens, food processing plants, and other areas where food is handled, floor coving prevents debris and bacteria from accumulating in corners, ensuring a hygienic environment and compliance with health regulations.

Industrial and Commercial Kitchens: To comply with health and safety regulations, these environments often require floor coving to ensure that cleaning is thorough and efficient.

Healthcare Facilities: In hospitals, clinics, and laboratories, floor coving is essential to prevent the buildup of dirt and bacteria in the corners where the floor meets the wall. This helps maintain a sterile environment.

Cleanrooms: In industries such as electronics, aerospace, and biotechnology, cleanrooms are used to minimize environmental contaminants. Floor coving helps maintain the required cleanliness standards by making the floors easier to clean.

Bathrooms and Restrooms: In public and commercial restrooms, floor coving can help prevent water damage and mold growth by sealing the joint between the floor and the wall.

Animal Care Facilities: In veterinary clinics, kennels, and animal shelters, floor coving aids in maintaining cleanliness and hygiene by preventing the accumulation of waste and dirt in corners.

Contact us about anything related to our company or services.

We'll do our best to get back to you as soon as possible.

- Carmat Coating and Allied Products Inc.

- Blk 1 Lot 5, Missouri St., Landmark Subd.,

Brgy. Parian, Calamba City, Laguna

- +63 (049) 545 7460

- sales@carmacoat.com