What Affects the Durability of Epoxy Flooring?

Published on January 2024

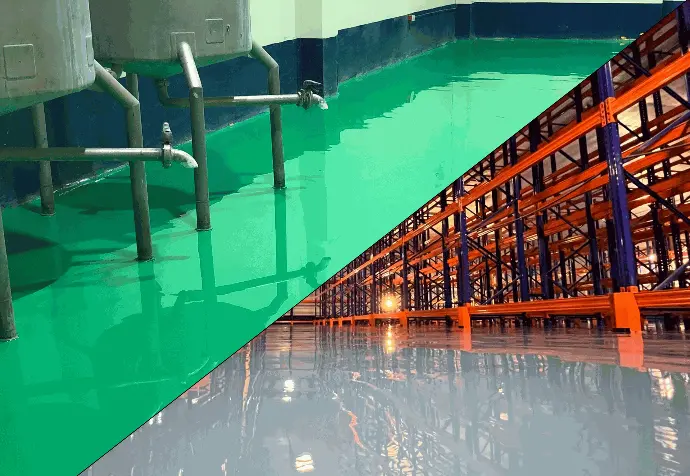

Besides its qualities of being chemical resistant, long wearing, color retaining, and easy to maintain, epoxy floors are best known for their durability and strength among other resin flooring. It is the ideal option for commercial and industrial applications as it's expected to withstand extreme conditions for a long span of time. Although epoxy floors are truly durable, there are factors that can affect its lifespan that are not considered prior to the flooring application.

Condition of concrete substrate

The condition of the underlying concrete surface is one of the most important factors to consider when planning an epoxy flooring installation. If the concrete shows surface defects, it can be alleviated by proper surface preparation but if it has deep structural defects, it will affect the durability of epoxy flooring in the long run. Concrete surfaces that have contaminants present such as oil, grease, or wax also affect the durability of the epoxy flooring, specifically by compromising its adhesion to the concrete.

Surface preparation

Before applying the epoxy flooring on the concrete surface, it first has to be surveyed for surface defects and other problems that could prevent the epoxy coat from adhering to the concrete properly. Concrete surface defects that are identified during surface preparation include blisters, dusting, delamination, cracks, low spots, spalling, and scaling & mortar flaking. Surface preparation should eliminate these defects as well as other problems that were identified during the survey, if not it can pose a possible threat to the epoxy flooring's integrity in the long run.

Quality of materials and application

It is important to determine which epoxy floor coating and which coat thickness is best suited for the area that will be worked on before the purchase and application of epoxy coats and related products. Ideally, it should be applied by an expert flooring solutions provider to ensure that no product is wasted and no mistakes are made during the application. This is because, besides the heavy equipment needed for surface preparation, epoxy products require their own set of special equipment, and have more specific procedures as well as curing times to follow before the ideal epoxy flooring is achieved. With specialty paints like epoxy resin, it isn't recommended to figure out the process as you go since it is more expensive and time-consuming to fix mistakes in epoxy applications relative to regular paint applications. Identify which flooring is best for you and apply it seamlessly with the help of flooring experts to ensure that the durable epoxy flooring you desire is achieved.

Environment

The environment in which the epoxy flooring will be applied should always be taken into consideration before the start of the process. For the epoxy flooring to last longer, it should be suitable for the environment it will be applied in because although it is built to last in a normal environment, under extreme conditions some epoxy flooring types are more suitable than others.

Traffic types and levels

Heavy foot traffic, machinery and equipment, like forklifts for example, will require an epoxy floor that is designed to withstand the load and activity of such environments. The standard epoxy floor coating will likely not withstand such environments until the end of its projected life cycle. It will need regular recoating or a replacement with a better suited coat.

Chemical exposure

Standard epoxy floor coatings are chemical resistant to a certain degree but under extreme and regular exposure to chemicals, it is likely that it will wear down faster than its projected life cycle. There are epoxy coatings specially formulated to withstand extreme chemicals but standard epoxy coatings will likely need to be replaced frequently under such circumstances.

Maintenance practices

For a standard epoxy floor coating to last, it must be properly maintained and kept free from dirt, debris, chemical spills and similar things that can damage it. Any cracks or chips found should be repaired before it translates into bigger damages on the flooring. It's best to consult your flooring solutions provider if other damages have been suffered by your epoxy flooring.

Tags: epoxy, epoxy floor painting, epoxy floor, epoxy floor coating, epoxy coating, industrial epoxy flooring, durability of epoxy

Suggested articles

Common Mistakes in Epoxy Applications

January 2024

Epoxy coating vs Self-leveling epoxy

January 2024

Contact us

Durability You Can Stand On

Request a quote or inquire about our services further by clicking the button below