Industrial Floor Coating

We provide industrial-grade epoxy flooring solutions that cater to your company's need for durable floors,

from surface preparation to floor coating application.

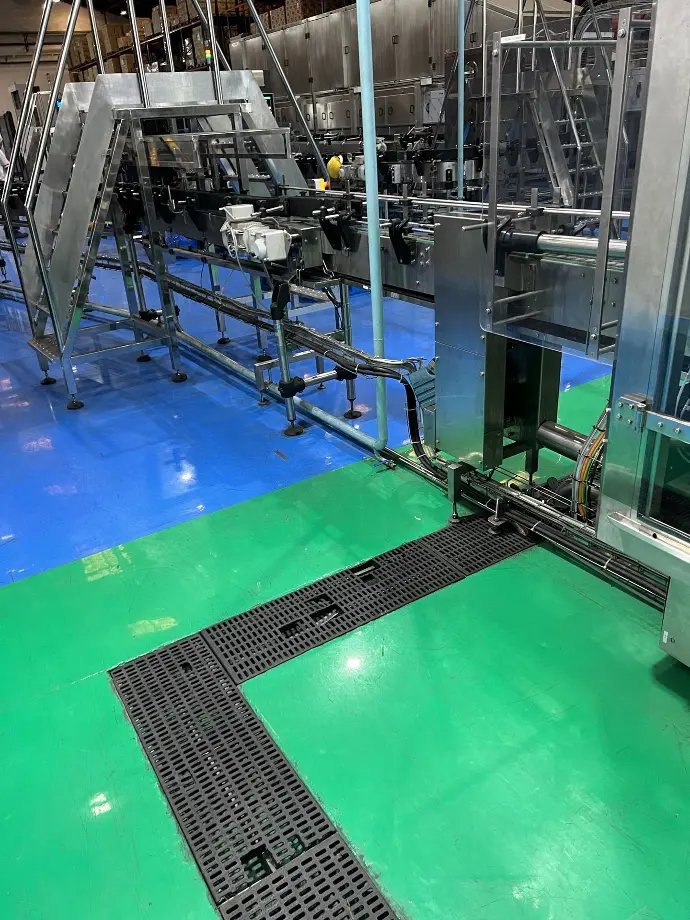

Before & After

Photo was taken 18 months after application. The area is used in a bottling process with heavy foot traffic and moving of pallets using pallet jacks. Photo was taken 18 months after application. The area is used in a bottling process with heavy foot traffic and moving of pallets using pallet jacks.

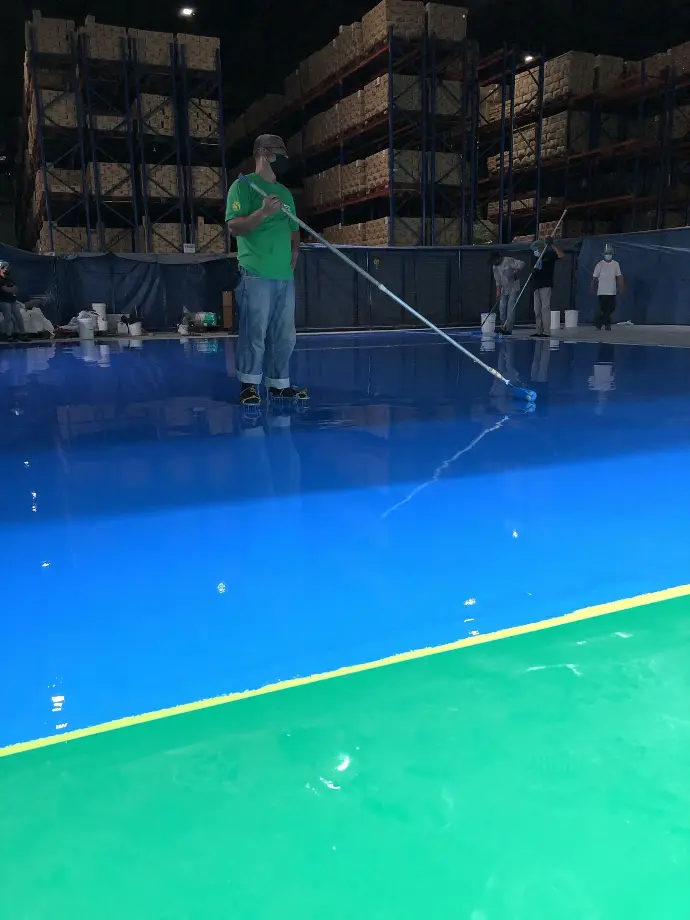

Case study: High-solids, Low-VOC paint.

A high-solids epoxy paint has lower volatile organic compounds (VOC). The solid contents in an epoxy paint is inversely proportionate to the VOC. This means that high-solid paints has a low-VOC, while low-solids has high-VOC. The higher the VOC the greater the organic compounds present in the paint that will evaporate from liquid to gas phase (volatility) during the curing process. These VOC can be identified by a strong rancid smell. High-solids epoxy paints can be difficult to apply as it is less viscous compared to ordinary paint. Epoxy paints that are available off the shelf usually have a high-VOC. The high-VOC have a lower viscosity making is easier to apply and has a better coverage area per liter. Carmacoat EPX paint is a two (2) component, high-solids low-VOC paint. The two components are composed of the paint and a hardener. Two-component paints dries and cures based on a chemical process. While single component paints are designed dry by exposing to air.

A client requested for a product demo on a busy portion of their storage facility. The area for demo had an existing coating that was already delaminating. An area of four (4) square meters was prepared and then coated using Carmacoat EPX paint. After a few months of observation, the performance of the Carmacoat EPX was far superior than the previously applied coating. The client decided to have a bigger potion of the facility coated.

The Carmacoat EPX (center) appeared to be thicker compared to the existing coating.

The existing coating (left) delaminated as the planetary grinder passed thru both coatings as part of the surface preparation.

The entirety of the Carmacoat EPX remained intact thru out the concrete grinding process.

Worst case scenario

Photo was taken two years after installation. This palettizing area operates throughout the whole year. Finished goods are stacked on top of the pallets. A fork lift is used to picks up the pallets from the area.

Durability You Can Stand On

Request a quote or inquire about our services further by clicking the button below