FS12 Concrete Grind and Seal

0.8mm-1.2mmthick | Industrial grade

Concrete grind and seal is a process used to enhance the appearance and durability of concrete surfaces. It involves grinding and polishing the concrete to a smooth finish, followed by the application of a sealant to protect against stains, moisture, and wear. This process not only improves the aesthetic appeal of the concrete but also increases its resistance to damage, making it suitable for various indoor and outdoor applications.

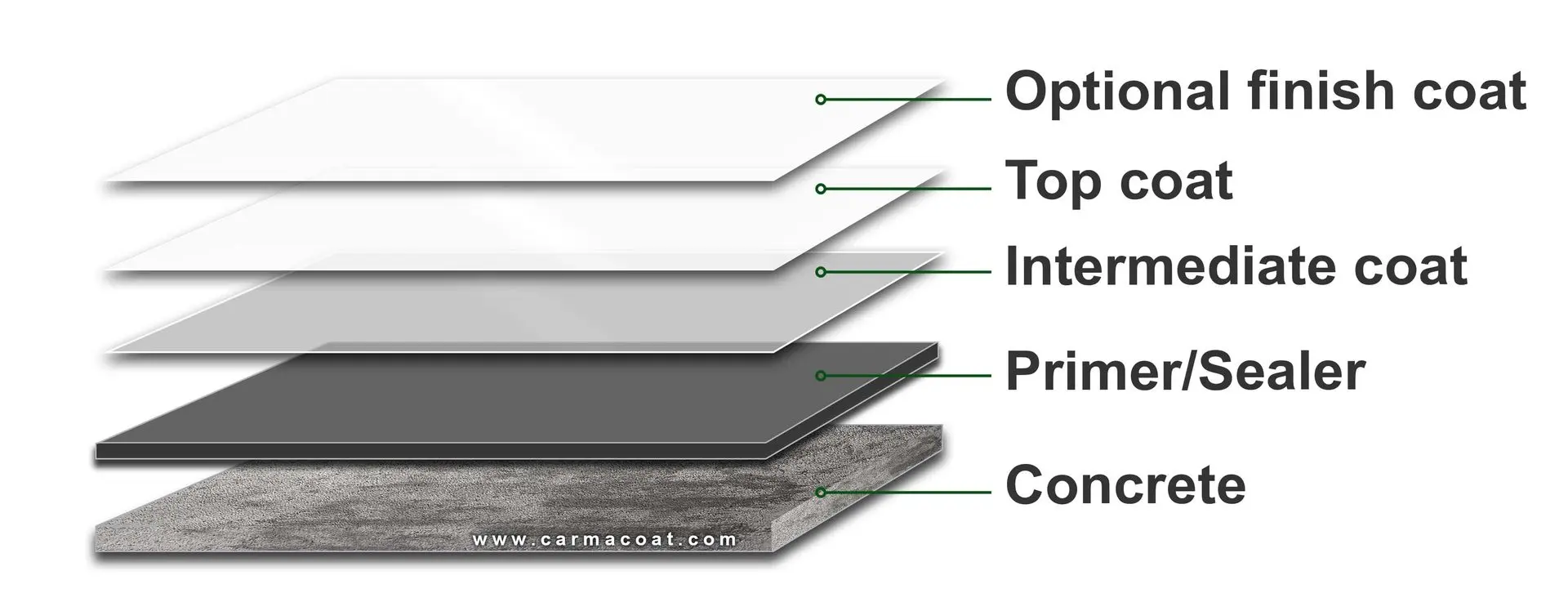

Floor Coating System

Carmacoat Concrete grind and seal involves several steps to ensure a smooth durable and attractive finish.

- Surface Preparation: This involves grinding the concrete surface to remove any existing coatings, dirt, oil, or imperfections. Proper surface preparation is essential for ensuring proper adhesion of the epoxy coating and achieving the desired finish.

- Primer/Sealer: After the surface has been properly prepared, a primer or sealer is applied. The primer serves as a bonding agent between the concrete substrate and the epoxy coating, ensuring strong adhesion and preventing delamination. Additionally, the primer helps to seal the concrete, reducing the risk of moisture vapor transmission and enhancing the overall performance of the epoxy system.

- Intermediate coat: Depending on the specific requirements of the project, an intermediate coat may be applied between the primer/sealer and the top coat of epoxy. The intermediate coat serves as a build coat, providing additional thickness to the epoxy system and improving its durability and resistance to wear and tear. It also helps to smooth out any imperfections in the substrate and enhance the overall appearance of the floor.

- Topcoat: Typically formulated with additives such as UV inhibitors and abrasion-resistant materials to provide enhanced protection and durability. The top coat also determines the final appearance of the floor, including its color, gloss level, and texture. It is important to choose a top coat that meets the specific aesthetic and performance requirements of the project.

- Optional Finish Coat: In some cases, an optional finish coat may be applied on top of the epoxy system to further enhance its appearance and performance. This could include additional layers of clear epoxy for added protection and gloss, or specialty coatings such as polyaspartic or polyurethane sealers for increased chemical resistance and durability. The finish coat can be customized to achieve the desired look and performance characteristics for the specific application

Benefits

Let's take a look at just six of the many perks you get when you go for grind and seal concrete floors over polished ones

-

Fast Installation: This can be quite the time commitment, taking anywhere from seven to ten days to install due to the extensive prep work and the process itself. On the flip side, grind and seal concrete is a quicker option, usually wrapping up in just two to three days.

- Cost-Effective: Grind and seal flooring offers potential savings in the long term. Notably durable, these floors often require minimal repair or replacement for many years, especially in residential or moderately trafficked areas. Additionally, their low-maintenance nature spares you the expenses associated with regular upkeep.

- Chemical Resistance: Warehouses, food plants, and kitchens are prime spots for concrete flooring, but they also share a common challenge: oil, grease, exposure to water, and food stains. Polished concrete isn't the best choice for these areas because if liquids like these aren't cleaned up promptly, they can cause damage over time. Enter grind and seal concrete floors. With a urethane sealer that forms a watertight barrier, these floors don't allow chemicals or liquids to seep in, making them a superior choice for such spaces. This means you can breathe easy knowing that water and other potentially hazardous liquids won't penetrate the floor or creep into your walls.

- Protection for Concrete: By sealing the concrete surface, epoxy coatings help protect it from moisture intrusion, staining, and surface damage, prolonging the life of the concrete substrate.

- Environmentally Friendly: Epoxy coatings are low VOC (volatile organic compound) and environmentally friendly once cured, making them a sustainable flooring option.

- Enhanced Durability: Epoxy coatings create a durable surface that can withstand heavy foot traffic, impact, and abrasion better than untreated concrete.

Application

FS12 Concrete grind and seal epoxy flooring are commonly used for a wide variety of industries and buildings including:

- Commercial Spaces: Epoxy-coated floors are popular in commercial settings such as retail stores, restaurants, hotels, and office buildings. They can withstand high foot traffic and provide a clean, attractive surface that enhances the overall ambiance of the space.

- Industrial Facilities: In industrial environments such as warehouses, manufacturing plants, and distribution centers, epoxy coatings offer excellent resistance to chemicals, oils, and heavy equipment traffic. They provide a durable and easy-to-clean surface that can withstand the rigors of industrial operations.

- Garages and Workshops: Epoxy-coated floors are a popular choice for residential garages, as well as automotive repair shops and other workshops. They are resistant to stains, spills, and abrasion from tools and equipment, making them ideal for high-traffic areas where durability is essential.

- Healthcare Facilities: Epoxy coatings are used in healthcare facilities such as hospitals, clinics, and laboratories due to their seamless, hygienic surface that is easy to clean and maintain. They can also be formulated with antimicrobial properties to help prevent the growth of bacteria and other pathogens.

- Educational Institutions: Schools, universities, and other educational facilities benefit from epoxy-coated floors in areas such as gymnasiums, cafeterias, and hallways. The durable, slip-resistant surface provides a safe and functional environment for students and staff.

- Showrooms and Exhibition Spaces: Epoxy-coated floors are often used in showrooms, galleries, and exhibition spaces to create a visually stunning backdrop for showcasing products and artwork. The glossy finish and seamless surface enhance the overall presentation while providing durability and easy maintenance.

If you're eager to address your concrete flooring concerns once and for all, don't hesitate to reach out to us today. We're here to help and would be delighted to offer you a free estimate, bringing you one step closer to turning your vision for stunning floors into a tangible reality.