FS22 Slip-Resistant

3-Coats Epoxy Floor Coating | 1.00mm - 1.40mm thick

TDS

A high-performance, solvent-free,

flooring system with excellent durability

and gloss designed for medium foot

traffic applications. It is a slip-resistant

floor coating that creates a textured and

seamless floor finish.

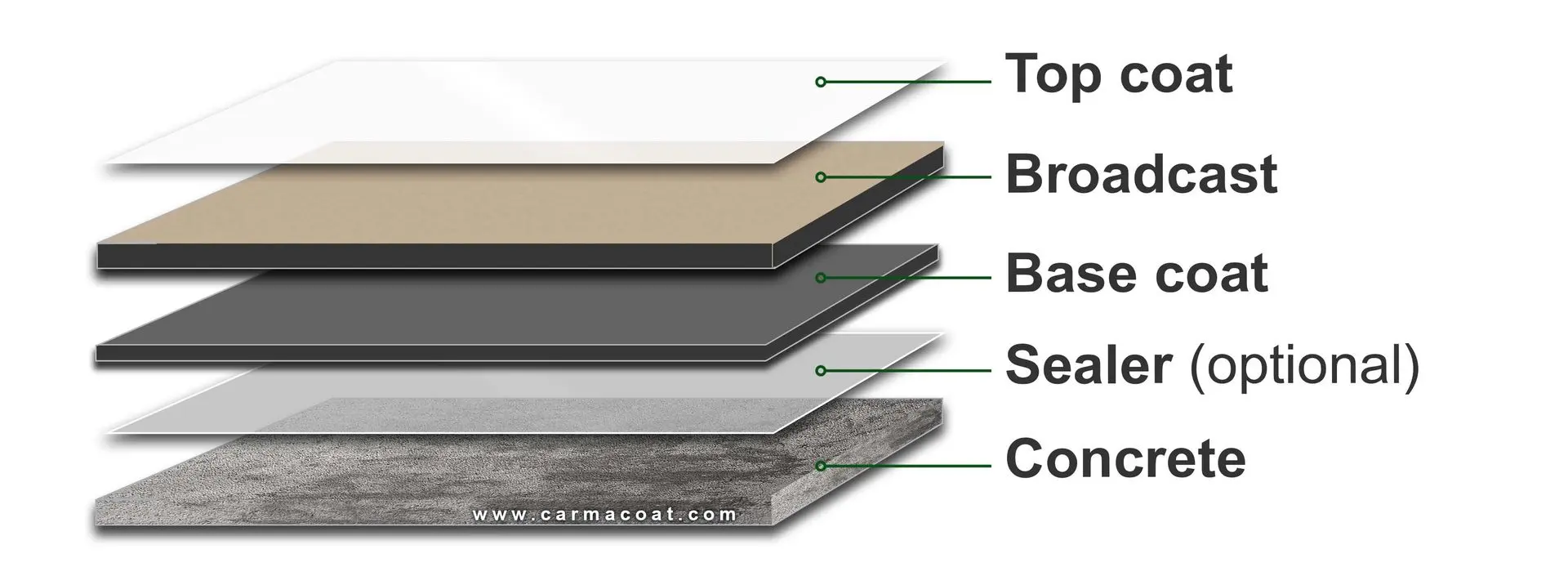

Floor Coating System

- Surface Preparation: A step to ensure proper adhesion of the epoxy coating. It involves cleaning the surface thoroughly to remove any dirt, grease, oil, or other contaminants. Depending on the condition of the surface, it may also involve grinding, shot blasting, or other mechanical means to create a rough profile for better adhesion.

- Sealer (optional): This is the initial layer applied to the floor surface. It serves to seal the surface and create a bond with subsequent layers. The sealer also helps to prevent moisture penetration and enhances the adhesion of subsequent layers.

- Base coat: Following the sealer, a base coat is applied. This layer provides additional durability, floor thickness, and slip resistance.

It is typically a pigmented epoxy resin that provides the primary color and thickness of the floor coating system.

For wall edges, a paintbrush should be used for a more precise application

- Broadcast: A full sand broadcast is done to provide additional durability, floor thickness, and slip resistance. Broadcast the sand on the wet epoxy primer to allow it to be embedded in the layer. This must be done within 20 minutes of the midcoat application before the midcoat has reached the later stages of curing. Allow a minimum of four hours of curing before applying another epoxy layer.

- Topcoat: After mixing the self-priming topcoat, apply it using a roller. For wall edges, a paintbrush should be used for a more precise application. For the topcoat application, a spike roller is used on the wet paint after application to eliminate any air bubbles and to facilitate better spread of the coating. Personnel are recommended to be equipped with spiked shoes to not ruin the coating .

Benefits

- Enhanced Safety: The primary benefit of slip-resistant floor coatings is improved safety. These coatings reduce the risk of slips, trips, and falls, especially in areas prone to wet or oily conditions. By providing traction and grip underfoot, slip-resistant coatings help prevent accidents and injuries, making them ideal for workplaces, commercial spaces, and public areas.

- Compliance: Many industries and regulatory bodies have specific safety standards and regulations regarding slip resistance. Using slip-resistant floor coatings helps businesses and property owners comply with these requirements, avoiding potential fines, penalties, and liability issues associated with non-compliance.

- Versatility: Slip-resistant coatings can be applied to various substrates, including concrete, metal, wood, and tile. They are suitable for a wide range of environments, including industrial facilities, commercial kitchens, warehouses, garages, hospitals, schools, and recreational areas.

- Durability: Slip-resistant floor coatings are typically made from durable materials such as epoxy or polyurethane, which are resistant to abrasion, chemicals, and heavy foot traffic. These coatings provide long-lasting protection for the underlying substrate, extending the life of the floor and reducing maintenance costs over time.

- Ease of Maintenance: Slip-resistant coatings are designed to be easy to clean and maintain. Their smooth and seamless finish prevents dirt, grease, and liquids from penetrating the surface, making them resistant to stains and contaminants. Regular cleaning with mild detergents or cleaners helps preserve the appearance and performance of the coating.

- Aesthetic Appeal: Slip-resistant floor coatings are available in a variety of colors, textures, and finishes, allowing for customization to match the aesthetic preferences of the space. They can enhance the appearance of floors while providing functional benefits, making them a popular choice for both commercial and residential applications.

- Cost-Effectiveness: Despite the initial investment required for installation, slip-resistant floor coatings offer long-term cost savings by reducing the risk of accidents, minimizing downtime due to injuries or repairs, and extending the lifespan of the floor. Additionally, the ease of maintenance reduces ongoing cleaning and upkeep expenses.

Application

Some recommended areas to apply FS22 Slip resistant floor coatings include:

- Commercial Kitchens: Commercial kitchens are prone to spills, grease, and water, creating slippery conditions that can lead to accidents. Slip-resistant floor coatings provide traction and grip underfoot, reducing the risk of slips and falls for kitchen staff.

- Industrial Facilities: Manufacturing plants, warehouses, and industrial facilities often have high foot traffic and are exposed to oils, chemicals, and other hazardous substances. Slip-resistant floor coatings help improve safety in these environments by providing traction on slippery surfaces.

- Retail Stores: Retail stores, supermarkets, and shopping malls experience heavy foot traffic, especially during peak hours. Slip-resistant floor coatings can help prevent accidents and injuries among customers and employees, particularly in areas prone to spills or moisture buildup.

- Healthcare Facilities: Hospitals, clinics, and medical centers require flooring solutions that prioritize safety and cleanliness. Slip-resistant floor coatings help reduce the risk of slips and falls in patient rooms, hallways, and other high-traffic areas, enhancing the overall safety of the facility.

- Educational Institutions: Schools, universities, and daycare centers accommodate students of all ages, making safety a top priority. Slip-resistant floor coatings can be applied in classrooms, gymnasiums, cafeterias, and corridors to minimize the risk of accidents and injuries among students, teachers, and staff.

- Hotels and Resorts: Hospitality establishments such as hotels, resorts, and spas aim to provide a safe and enjoyable experience for guests. Slip-resistant floor coatings in bathrooms, pool decks, and other recreational areas help prevent slips and falls, enhancing guest satisfaction and loyalty.

- Public Areas: Public buildings, government offices, airports, and transportation hubs accommodate large numbers of people daily. Slip-resistant floor coatings can be installed in lobbies, entranceways, staircases, and corridors to ensure the safety of visitors and employees.

- Outdoor Spaces: Outdoor areas such as patios, walkways, pool decks, and recreational areas can become slippery when wet or exposed to environmental elements. Slip-resistant coatings designed for outdoor use provide traction and grip, reducing the risk of accidents and injuries in these areas.

- Garages and Parking Lots: Residential garages, parking garages, and parking lots are exposed to vehicle fluids, oil, and water, posing slip hazards for pedestrians and drivers. Slip-resistant floor coatings enhance safety for both pedestrians and vehicles, reducing the risk of accidents and injuries.

Conclusion

Carmacoat FS22 Slip resistant floor coatings offer a winning combination of safety, durability, and aesthetics, making it an ideal choice for a wide range of applications. By following the proper application process and choosing high-quality materials, property owners can enjoy long-lasting flooring solutions that enhance both safety and functionality in their spaces. Whether in commercial kitchens, manufacturing facilities, retail spaces, or healthcare facilities, epoxy coatings provide peace of mind and a solid foundation for any environment.

If you're eager to address your concrete flooring concerns once and for all, don't hesitate to reach out to us today. We're here to help and would be delighted to offer you a free estimate, bringing you one step closer to turning your vision for stunning floors into a tangible reality.